Product blending: total visibility to make the right strategic choices

Product blending: a classical resource allocation problem

Product Blending is a classical resource allocation problem (allocating components to products) and a natural application of mathematical programming.

There are several ways a blend optimization problem can be addressed:

Online single product blending: this is a real-time adjustment of the rates of various components in order to keep the blend constantly on specs; it also takes into account an optimization criterion based on component values or quality giveaway penalties

Multiple blend optimization is about allocating multiple components to multiple blends; this can take place in 2 different time frames:

- Within a planning (LP) context, the model is typically run with 1 period, which means that all components are assumed to be available at any point in time: this is obviously not feasible in practice.

- Within a scheduling context, since the components availability is known on a day-to-day basis, the optimal allocation to the final blends is realistic and feasible in practice

There is an important variability in product blending situations among refineries depending on:

- The market context: are there any breathing opportunities in the market in terms of imports and exports of small amounts of products or components?

- The refinery tank configuration: running-gauge situations, tank rotations, hot rundown blending…

Multiple product blending optimization

Multiple product blending optimization is generally considered to be the most flexible approach to solving the resource allocation problem.

It is by far more economical than optimizing the mix of single products, as the allocation of components to products is much more flexible, and quality excesses can be significantly minimized.

Optimix: an intuitive multiple Product Blending optimization system with unique advanced features

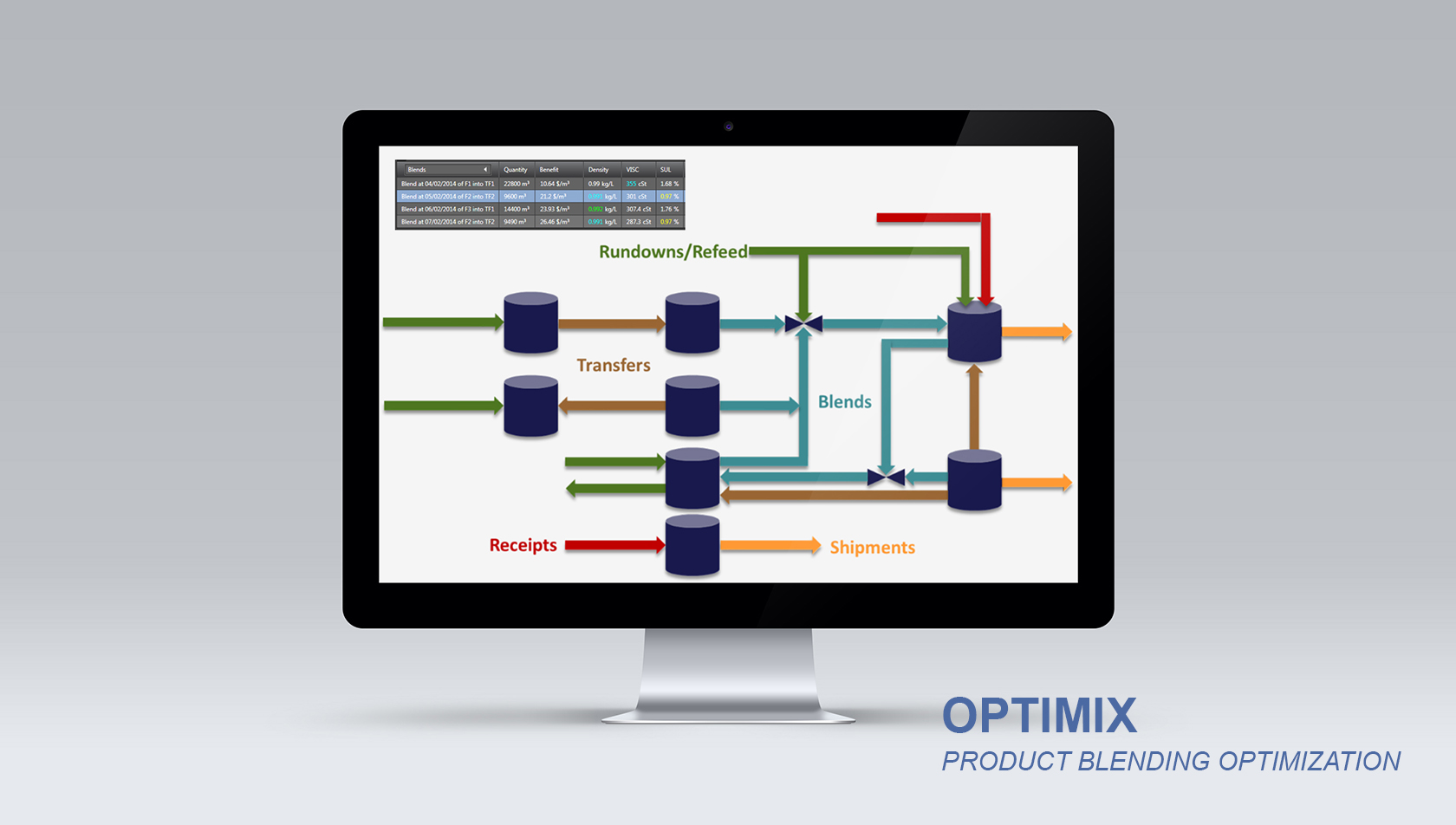

Optimix for multi-period product blending optimization is a software application part of the Princeps Planning & Scheduling Suite that enables the refinery schedulers to optimise product blending and realise higher value out of the available components.

Optimix can perform multi-period multi-blend optimization over a planning horizon of several weeks. It is a generic tool that can be easily configured to any refinery and bring instant value for money.

The Optimization criterion can be total profit (revenue-costs), or penalties on quality specifications giveaway, which is another way of allocating values to components. Other penalty factors can be introduced at various points in order to achieve smooth operations

Besides the standard operations

Optimix can easily handle complex situations recurrent in oil product blending like these 5 elements :

- Tanks containing components or finished products and potentially connected to other units of the refinery through input or output flows

- Linear and non-linear blending correlations

- Blender logistics

- This system is considered within a given time frame during which various tank operations can be scheduled : receipts, shipments, transfers or blends.